Sm@rtLine Data Cockpit

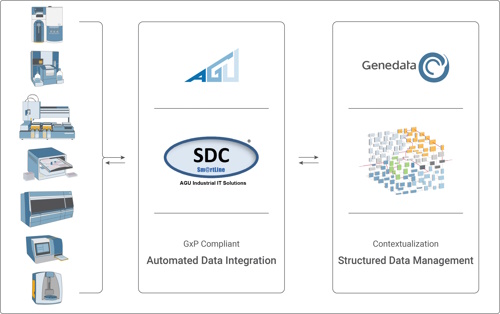

Sm@rtLine Data Cockpit is a unique software middleware which enables the use of sensors and analyzers for the collection, review and approval of trial results. SDC provides flexible and modern interfaces to transfer the device data to higher level systems like MES, ELN, LIMS or Historian systems. Automate your data handling and use SDC as a black-box system or use the SDC web UI to implement approval and review steps.

What is SDC?

Close the gap between LIMS, MES, DCS and the laboratory devices

SDC is a middleware which is placed between the sensors and the analyzers for the BIO-API processes and the interface to ERP (enterprise ressource planning), LIMS (laboratory information system), MES (manufactoring execution system) and DCS (distributed control system) systems. SDC provides standardized, flexible interfaces for these systems which deliver calculated and evaluated data.

Increase your knowledge

The technican is no longer required to manually start and read measurements from the devices, but rather, the measurements for these devices are reported centrally on the SDC server. SDC allows you to measure faster and more frequently and save the evaluated data in a central system. From this data, you can form golden batch and compare your measurement and calibration curves together with multiple analyzers in a graph.

Improve your quality

SDC supports your implementation of PATH / QbD (Process Analytical Technology / Quality by Design). These concepts strive to ensure a predefined product quality by implementing measures to improve understanding of the manufacturing process by using real-time measuring for all attributes. SDC supports these requirements by providing data transparency, reliability and traceability instead of manual measurement, where accuracy of data and precisely timed sampling cannot be guaranteed.

Reduce your costs

SDC incorporates validated interfaces which have been approved by our many satisfied customers. This reduces your costs for validation and integration of the analyzers as well as reducing costs for the validation of the data handling. Overall, your costs are optimized through the improved data quality, your reaction time improves, production is streamlined and yield can be increased.

Web based

SDC is a web- and database centered server platform that can be used from every client without special installation.

Safe rights management

SDC includes management of user rights which guarantees safe access to data.

Remote control

SDC is capable of controlling analyzers remotely so that the operator is using one consistent GUI when performing his tasks.

Control

The operator can create, start and evaluate the analyzer measurements in a central system. The approved results can be uploaded to a foreign system (e.g. LIMS, MES or ERP).

Calculate

SDC offers the functionality of generating measurement results based on the data retrieved from the analyzers. Available calculation methods include averaging and trypsinization.

Multiple devices

SDC gives you the ability to combine a multitude of analyzers and sensors to form one system and to evaluate and compare the results.

Middleware

SDC is a middleware between LIMS, MES and DCS systems and the laboratory areas "research", "development" and "production".

Centralized data

SDC provides a central master data management of devices, samplings, samples and users.

Compare

SDC gives you the ability to compare measurements from research, development and production (e.g. interface calibration data) comprehensively.

What can SDC do for you?

General benefits

Reliability of data

SDC shortens measurement times, which leads to more frequent data and therefore to more knowledge about correllations between critical parameters. Reproducable and automated cell culture analysis improves the reliability of data.

Central database

The central database provides a unique point of information. Data-analysis occurs within ONE database and not in many different databases. Efficient data-evaluation occurs in One system for flexible data-analysis and reporting.

Global visibility

Global data collection increases the visibility of different processes. Global task sharing is facilitated.

Data availability

SDC delivers the data simply and transparently. The operator saves valuable time on the preparation of measurements and data transfer.

Transparency and traceability

SDC makes a comprehensive correlation of analyzer and sensor measurements in research, development and production possible and creates transparancy and traceability.

Calibration data

Calibration data during a product lifecycle (research, development and production) can be compared and contrasted regardless of the device used.

User benefits

Sample handling

Measurements can be repeated easily and they can be prepared while the analyzers are still working. It is possible to monitor measurement progress from anywhere within the company‘s network, including status observation of devices and calculation of time remaining. The measuring procedures of the analyzers are controlled without further user action.

Data evaluation / calculation

Individual measurement results of the analyzers and sensors can be evaluated and calculated into a single result (e.g., mean value, trypsinization). Measurement results can be evaluated / calculated according to batch ID and then displayed graphically in a „time cultivation chart“. The integrated batch comparison enables comparison with the golden batch.

Intuitive system

SDC’s modern and intuitive operating concept is grounded in practical experience, resulting in wide acceptance and minimizing need for on-the-job training.

Validation effort

SDC reduces the validation efforts tremendously by replacing the manual transaction and processing of data by the user.

GMP conforming data handling

Paperless data handling of measurements and data transfer to foreign systems (LIMS, MES, ERP) occurs with electronic signatures and change logs in consideration of 21 CFR Part 11. This ensures the data integrity of all measurements and further parameters. The operator can transfer data for special reports or evaluations easily to Excel.

IT benefits

Remote solution

SDC can be used as a remote solution for facilities regardless of location. Due to its integrated web technology, SDC can be used within the complete network centrally or remotely. Due to modern web technology, no additional installation work is necessary at the client site.

Interfaces

SDC has an open interface concept that enables the connection of LIMS, MES and ERP through XML, SQL and OPC.

New analyzers

The adapter concept for the connection of analyzers and sensors allows for a continual expansion of the system.

Administration

User administration (user- and rights-management) can be linked to the active directory.

Backup

SDC supports the central data backup of results and images.

Setup

A setup oriented toward master data enables conformity and expandability.

IT concept

SDC is a fully developed .NET technology with an Ajax GUI framework and MVP architecture.

Production benefits

Real time

Real-time data leads to more accurate process adjustment. Real-time monitoring increases process understanding.

Ready for automation

SDC creates the basis for future automated processes. The development data can be compared to the production data and all process information (sensors and analyzers) can be viewed on a common timeline. The golden batch can be formed through real-time monitoring for „Closing the Loop“ (QbD = Quality by Design).

Boost of quality and yield

More effective and faster processing time of trials makes more frequent measuring possible, optimizes process monitoring and boosts both quality and yield.

Consolidation

With SDC, the user can consolidate all sensors and analyzers used in fermentation research, development and production into a single system. This method makes the work easier and safer.

Supported Instruments

| Manufacturer | Model | Type | Technology | Status | Price-Kat |

|---|---|---|---|---|---|

| 908 devices | Rebel | Cell Media Analysis | File | Available | B |

| Advanced Instruments | Model 2020 | Osmometer | RS232 | Available | A |

| Advanced Instruments | Model 3250 | Osmometer | RS232 | Available | A |

| Advanced Instruments | Model 3320 | Osmometer | RS232 | Available | A |

| Advanced Instruments | Model A2O | Osmometer | RS232 | Available | A |

| Advanced Instruments | Model OsmoPro | Osmometer | TCP | Available | A |

| Advanced Instruments | Model OsmoTech | Osmometer | TCP / Web-Interface | Available | A |

| Advanced Instruments | Model OsmoTech HT | Osmometer | TCP (OPC UA) | Available | B |

| Advanced Instruments | Model OsmoTech Pro | Osmometer | TCP (OPC UA) | Available | A |

| Advanced Instruments | Model OsmoTech XT | Osmometer | TCP (OPC UA) | Available | A |

| Agilent | 1200 Series | HPLC | File | Available | C |

| Agilent | 5977B MSD | Gas chromatograph mass spectrometer | File | In development | |

| Agilent | Cary 3500 UV-Vi | Spectrophotometer | REST-API | In development | B |

| Agilent | RapID | Raman spectrophotometer | File | On Request driver is feasible | |

| Anton Paar | DMA 1001 | In development | |||

| Anton Paar | DMA 4100M | Density and concentration | On Request driver is feasible | ||

| Anton Paar | DMA 4500M | Vibration type digital density meter | RS232 | On Request driver is feasible | |

| Applied Biosystems | 3500 Genetic Analyzer | DNA sequencer | File | On Request driver is feasible | |

| Arkray Infinity | OM-6060 | Freezing point depression | RS232 | Available | B |

| ATAGO | RX-5000α | Refractometer | RS232 | On Request driver is feasible | |

| Bayer Technology Service | BaychroMAT | Automated Sampling | TCP | Is no longer supported | |

| Beckman Coulter | HIAC 9703+ Liquid Particle Counter | Light shielded automatic fine particle counter | File | In development | |

| Beckman Coulter | Metaflex | Available | B | ||

| Beckman Coulter | PA800plus | Capillary electrophoresis apparatus | File | In development | |

| Beckman Coulter | Vi-Cell Blu | Cell Counter | File / TCP (OPC UA) | Available | B |

| Beckman Coulter | Vi-Cell XR | Cell Counter | File | Available | B |

| bioMérieux | 3P Station | Fully automated microbial culture colony counter | File | On Request driver is feasible | |

| BIO-RAD | ChemiDoc XRS plus | Chemiluminescence Fluorescence Colorimetry/densitometry | On Request driver is feasible | ||

| BioTek | ELx808 | Microplate reader | File | On Request driver is feasible | |

| BioTek | ELx808cse | Microplate reader | File | On Request driver is feasible | |

| BioTek | ELx808IU | Microplate reader | File | On Request driver is feasible | |

| BioTek | EPOCH2 | Microplate reader | On Request driver is feasible | ||

| Bruker | NIR Spectrometer | Spectrometer | On Request driver is feasible | ||

| BUCHI | N-500 | Near-infrared spectrophotometer | File | On Request driver is feasible | |

| C Technologies Inc. | SoloVPE | Slope Spectroscopy | File / RTF | Available | B |

| CAS | CI 153 CLiMET particle counter | Particle counter | Available | B | |

| ChemoMetec | NucleoCounter NC-202 | Nucleocounter | File | Available | A |

| ChemoMetec | Nucleocounter NC-200 | Cell counter | On Request driver is feasible | ||

| Cytiva | Biacore 1S | Surface Plasmon Resonance (SPR) | On Request driver is feasible | ||

| Dionex | Dionex HPLC (Chromeleon) | HPLC | On Request driver is feasible | ||

| FUJIFILM Wako Chemicals | ET-7000 | Toxinometer | On Request driver is feasible | ||

| GE Healthcare | ÄKTA | On Request driver is feasible | |||

| GE Healthcare | Sievers M9 | Total organic carbon (TOC) | Modbus TCP | On Request driver is feasible | |

| Gonotec | Osmomat 030 RS/D | Osmometer | RS232 | Available | A |

| Gonotec | Osmomat 3000/3000D | Osmometer | RS232 | Available | A |

| Gonotec | Osmomat auto | Osmometer | RS232 | Available | A |

| Hach Lange | DR 2800 photo meter | photo meter | USB | Available | C |

| Hach Lange | DR 3800 photo meter | photo meter | USB | Available | C |

| Hach Lange | DR 3900 photo meter | photo meter | USB / Ethernet | On Request driver is feasible | C |

| Hach Lange | TL2350 | Turbidimeter | File (requires development (e.g. Raspberry pi) or Magic Box) | Available | A |

| Hach Lange | TL2360 | Turbidimeter | File (requires development (e.g. Raspberry pi) or Magic Box) | Available | A |

| Heidolph | Overhead Stirrer Hei-TORQUE | Stirrer | RS232 | Available | A |

| HORIBA | LA-950V2 | Particle size analyzer | File | In development | |

| HORIBA | LabRAM HR Evolution | Micro-laser Raman spectrophotometer | File | In development | |

| Jova Solutions | FermWorks | Bioprocess Control | TCP/MS-SQL | On Request driver is feasible | |

| Kaiser Optical Systems | Raman Rxn2 | Raman spectroscopy | TCP (OPC UA) | Available | C |

| Knick | Knick Portavo 907 MULTI COND | cond | USB | Available | A |

| Knick | pH-Meter Calimatic 765 | pH | RS232 | On Request driver is feasible | |

| Knick | Portavo 907 pH | pH | USB | Available | A |

| Kyoto Electronics Manufacturing | DA-130N | density pycnometer | File | On Request driver is feasible | |

| Lighthouse Instruments | FMS-Oxygen Headspace Analyzer FMS-760 | Circular Dichroism-Fluorescence Spectroscopy (CD-FS) | File | Available | B |

| Lonza | PyroTec PRO | Automated Endotoxin Testing System | On Request driver is feasible | ||

| Malvern Panalytical | Epsilon 4 | X-ray fluorescence spectrometer | On Request driver is feasible | ||

| Malvern Panalytical | Mastersizer 3000 | Laser diffraction particle size analysis | On Request driver is feasible | ||

| Mecmesin | Vortex-dV | On Request driver is feasible | |||

| Metrohm | 780 pH Meter | pH temperature | RS232 | In development | B |

| Mettler Toledo | Compact Titration G20 / G20 S | Titration | LabX | Available | E |

| Mettler Toledo | Compact Titration V20 / V30 / C20 / C30 | Titration | LabX | Available | E |

| Mettler Toledo | D4 / D5 / D6 / R4 / R5 / RX4 / RX5 | Density/Refractometer | LabX | Available | E |

| Mettler Toledo | DM40 / DM45 / DM50 / RM40 / RM50 | Density/Refractometer | LabX | Available | E |

| Mettler Toledo | DX40 / DX45 / DX50 / RX40 / RX50 | Density/Refractometer | LabX | Available | E |

| Mettler Toledo | Excellence balances XP / XS / XPE / XSE – LabX | Scale | LabX | Available | E |

| Mettler Toledo | Excellence balances XP / XS / XPE / XSE – RS232/SICS | Scale | RS232 (SICS) | Available | A |

| Mettler Toledo | Excellence balances XPR / XSR – LabX | Scale | LabX | Available | E |

| Mettler Toledo | Excellence balances XPR / XSR – RS232/SICS | Scale | RS232 (SICS) | Available | A |

| Mettler Toledo | HS153 – Halogen-Feuchtebestimmer HS153 | TCP/IP direct connection | On Request driver is feasible | ||

| Mettler Toledo | MP70 / MP80 / MP90 | Thermal Value | LabX | Available | E |

| Mettler Toledo | Quantos automatic dosing systems: XP/XS/XPE | Scale dosing system | LabX | Available | E |

| Mettler Toledo | SevenExcellence Instruments | pH Conductivity | LabX | Available | E |

| Mettler Toledo | SevenExcellence Instruments (direct) | pH Conductivity | TCP (without Lab-X) | Available | B |

| Mettler Toledo | Titration Excellence T5 / T7 / T9 | Titration | LabX | Available | E |

| Mettler Toledo | Titration Excellence T50 / T70 / T90 | Titration | LabX | Available | E |

| Mettler Toledo | UV7/UV5/UV5Nano/UV5Bio | photo meter | LabX | Available | E |

| Mitsubishi Chemical Corporation | CA-310 | Micro-moisture analyzer | File | On Request driver is feasible | |

| Molecular Devices | SpectraMax 190 | Microplate reader | API or File | On Request driver is feasible | |

| Molecular Devices | SpectraMax iD3 | Microplate reader | API or File | On Request driver is feasible | |

| Molecular Devices | SpectraMax L | Microplate reader | API or File | On Request driver is feasible | |

| Molecular Devices | SpectraMax M3 | Microplate reader | API or File | On Request driver is feasible | |

| Molecular Devices | SpectraMax M4 | Microplate reader | API or File | On Request driver is feasible | |

| Molecular Devices | SpectraMax M5 | Microplate reader | API or File | On Request driver is feasible | |

| Molecular Devices | SpectraMax M5e | Microplate reader | API or File | On Request driver is feasible | |

| Molecular Devices | VersaMax | Microplate reader | API or File | On Request driver is feasible | |

| Molecular Devices | SoftMax Pro/Hamilton/SpectraMax | Liquid handling roboter | Is no longer supported | C | |

| Nippon Denko Kogyo | SE7700 | Spectrophotometer | On Request driver is feasible | ||

| Nova Biomedical | BioProfile 100 | Metabolite | On Request driver is feasible | ||

| Nova Biomedical | BioProfile FLEX | Metabolite Cell count osmometer | TCP (OPC DA) | Available | C |

| Nova Biomedical | BioProfile FLEX 2 | Metabolite Cell count osmometer | TCP (OPC UA) | Available | C |

| Nova Biomedical | BioProfile phOx | Blood Gas Analyzer | RS232 (ASTM) | Available | B |

| Nova Biomedical | Stat Profile Prime | In development | B | ||

| Optocell | CuBiAn HT | Metabolite | RS232 (ASTM) | On Request driver is feasible | C |

| Optocell | CuBiAn XC | Metabolite | RS232 (ASTM) | On Request driver is feasible | C |

| Pall | Palltronic Flowstar IV | Filter Integrity Tester | TCP (OPC UA) / File (XML) | Available | A |

| Pall ForteBio | Octet® RED96 | Bio-Layer Interferometry (BLI) | On Request driver is feasible | ||

| Particle Measuring Systems | Lasair III 310C | Particle counter | Modbus TCP | On Request driver is feasible | |

| Perkin Elmer | Frontier MIR/FIR with ES Spectrometer | Spectrometer | On Request driver is feasible | ||

| Perkin Elmer | Lambda 25/35 Spectrometer | Spectrometer | File | Available | A |

| Perkin Elmer | LAMBDA 365 | Spectrometer | File | Available | A |

| Pfeiffer Vacuum | ASM 2000 | Helium leak tester | On Request driver is feasible | ||

| Pfeiffer Vacuum | ME2 | Leak/Mass Extraction Tests | File | Available | B |

| ProteinSimple | Maurice C | Capillary electrophoresis apparatus | File | On Request driver is feasible | |

| Radiometer | ABL 805 | Blood Gas Analyzer | RS232 (ASTM) | Available | B |

| Rapid Micro Biosystems | Growth Direct | File | Available | C | |

| Repligen | SoloVPE | Slope Spectroscopy | Connection with Viper | Available | B |

| Rigaku | Progeny | Raman spectrophotometer | File | In development | |

| Roche Diagnostics | Cedex Bio | Metabolite | RS232 (ASTM) | Available | B |

| Roche Diagnostics | Cedex Bio HT | Metabolite | RS232 | Available | C |

| Roche Diagnostics | Cedex HiRes >= 2.4 | Cell Counter | TCP | Available | C |

| Roche Diagnostics | Cedex HiRes 2.2 | Cell Counter | TCP | Available | B |

| Roche Diagnostics | Cedex HiRes 2.3 | Cell Counter | TCP | Available | C |

| Roche Diagnostics | Cedex Standard | Cell Counter | TCP | Available | A |

| Roche Diagnostics | cobas b 123 | Blood Gas Analyzer | TCP (ASTM) | Available | A |

| Roche Diagnostics | cobas b 221 | Blood Gas Analyzer | TCP (ASTM) | Available | A |

| Roche Diagnostics | cobas c 311 | On Request driver is feasible | B | ||

| Roche Diagnostics | cobas e 411 | Immunoassays | RS232 (ASTM) | Available | C |

| Roche Diagnostics | cobas pure | HL7 | In development | C | |

| Roche Diagnostics | LightCycler480 Instrument II | Real-Time polymerase chain reaction (RT-PCR) | File | On Request driver is feasible | |

| Sartorius | ambr 15 | Automated bio reactor sytsem | TCP | Available | D |

| Sartorius | ambr 250 | Automated bio reactor sytsem | TCP | Available | D |

| Sartorius | Sartocheck 5 Plus | Filter Tester | TCP (OPC UA) | Available | C |

| Sartorius | Scales | Scale | RS232 (SBI Protocol) | Available | A |

| SHIMADZU | MSE-2400 | Helium leak tester | RS232 | On Request driver is feasible | |

| SHIMADZU | QTRAP 6500+ System | High-performance liquid chromatography (HPLC) | File | On Request driver is feasible | |

| SHL Medical | JOHO | Manual autoinjector testing machine | On Request driver is feasible | ||

| Siemens | Atellica NEPH 630 | Nephelometer | RS232 (ASTM) | Available | C |

| Siemens | BN II System | Nephelometer | RS232 (SerHost/AutoHost) | Available | C |

| Siemens | BN ProSpec | Nephelometer | RS232 (SerHost/AutoHost) | Available | C |

| Siemens | RAPIDLab 1200 Series | Blood Gas Analyzer | RS232 | Available | B |

| Siemens | RAPIDLab 1240 | Blood Gas Analyzer | RS232 | Available | B |

| Siemens | RAPIDLab 248 | Blood Gas Analyzer | RS232 | Available | B |

| Siemens | RAPIDLab 348 | Blood Gas Analyzer | RS232 | Available | B |

| Siemens | RAPIDLab 348 EX | Blood Gas Analyzer | RS232 | Available | B |

| Siemens | RAPIDPoint 500 | Blood Gas Analyzer | RS232 | Available | B |

| Siemens | Sysmex CS-2500 | On Request driver is feasible | B | ||

| TECAN | EVO | Liquid handling roboter | File API | Available | D |

| TECAN | Fluent | Liquid handling roboter | File | Available | D |

| TECAN | Infinite M200 | Plate Reader | File | Available | B |

| TECAN | Sunrise | Plate Reader | File | Available | B |

| Thermo Fisher | ICP Raman Spectrometer | Spectrometer | On Request driver is feasible | ||

| Thermo Fisher | Indiko | Metabolite | TCP | Available | C |

| Thermo Fisher | Konelab 20 | Metabolite | RS232 | Available | C |

| Thermo Fisher | Konelab 20 XT | Metabolite | RS232 | Available | C |

| Thermo Fisher | Konelab 60 | Metabolite | RS232 | On Request driver is feasible | C |

| Thermo Fisher | NanoDrop One/OneC | Spectral photo meter | File | Available | B |

| Thermo Fisher | VisionMate | Highspeed Barcode-Reader | File | On Request driver is feasible | C |

| Thermo Fisher Scientific | iN10 | Infrared spectrophotometer | File | On Request driver is feasible | |

| Thermo Fisher Scientific | Orbitrap 120 | High-performance liquid chromatography (HPLC) | File or database | On Request driver is feasible | |

| Thermo Fisher Scientific | Orion Versa Star Pro | pH/ISE/Conductivity | RS232 | In development | B |

| Thermo Fisher Scientific | TruScan RM | Raman spectrophotometer | File | On Request driver is feasible | |

| Thermo Fisher Scientific | Vanquish Horizon | High-performance liquid chromatography (HPLC) | File or database | On Request driver is feasible | |

| Thermo Scientific | Genesys 30 | File | Available | B | |

| ThermoFisher | VSTAR10 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR12 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR12 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR13 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR20 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR22 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR23 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR30 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR32 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR40A | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR40A2 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR40B | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR40B2 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR50 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR52 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR80 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR82 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR83 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR90 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR91 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR92 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR93 | pH/ISE/Conductivity | RS232 | In development | B |

| ThermoFisher | VSTAR94 | pH/ISE/Conductivity | RS232 | In development | B |

| Waters | Empower | HPLC | .Net | On Request driver is feasible | C |

| Werum | PAS-X | MES | MSI | Available | F |

| WESCOR | Osmometer | Osmometer | On Request driver is feasible | ||

| Wilco | Wilcomat W07 MC/LFC | Leak detection | File | On Request driver is feasible | |

| WTW | 3310 pH conductivity | pH cond | USB | On Request driver is feasible | A |

| WTW | 3420 | pH Conductivity | USB | Available | A |

| WTW | 3620 | pH Conductivity | USB | Available | A |

| WTW | 3630 | pH Conductivity | USB | Available | A |

| WTW | inoLab 7310 Cond | Conductivity | USB | Available | A |

| WTW | inoLab 7310 Oxi | Oxi | USB | Available | A |

| WTW | inoLab 7310 pH | pH | USB | Available | A |

| WTW | inoLab Multi 9310 IDS | pH cond | USB | On Request driver is feasible | A |

| YSI Life Sciences | YSI 2700 Select | Metabolite | RS232 | On Request driver is feasible | C |

| YSI Life Sciences | YSI 2900D | Metabolite | RS232 | Available | C |

| YSI Life Sciences | YSI 2950 | Metabolite | RS232 | Available | C |

| Zwick | AllroundLine | Tensile test Compression test Flexure test | File | On Request driver is feasible | |

| Zwick | zwickiLine | Autoinjector testing system | File | On Request driver is feasible |

Partners

Marketing and Product Partner (worldwide)

Roche GmbH

Sandhofer Str. 116

68305 Mannheim

Tel. +49 621 7590

mannheim.rdd-kommunikation(at)roche(dot)com

www.roche.com

www.custombiotech.roche.com

> click here to watch presentation <

System Partner

(worldwide)

Körber Pharma Software

Lars Hornung

(Sr. Principal - Alliances Technology Partners)

Wulf-Werum Str. 3,

21337 Lüneburg, Germany

Tel.: +49 175 4363675

lars.hornung(at)koerber(dot)com

www.koerber.com

System Partner

(USA)

JSat Automation

1730 Walton Road, Suite 100

Blue Bell, PA 19422, USA

Tel.: +1 267 903 1800

sales(at)jsautomation(dot)com

jsautomation.com

Interface Development Partner (USA)

Advanced Instruments, LLC

2 Technology Way

Norwood, MA 02062

Tel. +1 (781) 320 9000

info(at)aicompanies(dot)com

aicompanies.com

System Partner

(Ireland)

Focus Scientific Solutions

Unit 12 Block 3, City North Business Campus

Stamullen, Co Meath, K32 FA33

Tel. (353)1 8834 964

info(at)focusscientific(dot)ie

focusscientific.ie

System Partner

(USA)

Tetrascience

294 Washington Steet, 11th Floor

Boston, MA 02108

Tel. (857)244-1514

hello(at)tetrascience(dot)com

www.tetrascience.com

System Partner

(USA)

ZONTAL, INC.

1990 West New Haven Avenue | Suite 301

Melbourne, FL 32904

Tel. +1 (801) 949 6827

info(at)zontal(dot)io

www.zontal.io

System Partner

(Switzerland and Europe)

ControlTech Enginering AG

Benzburweg 7

CH - 4410 Liestal

Tel. +41 61 927 9900

Sascha.Zeller(at)cte(dot)ch

www.cte.ch

System Partner

(Singapore and Asia)

Integrix Solutions Pte Ltd

10 Anson Road #33-04A

International Plaza

079903 Singapore

Tel. +65 9369 8624

bingfai.kwong(at)integrixsolutions(dot)com

www.integrixsolutions.com

System Partner

(Israel and Middle-East)

Gamidor Diagnostics Inc.

Shacham Street 32

Petach Tikva

Tel. +972 03 927 7277

info(at)gamidor(dot)co(dot)il

www.gamidor.co.il

System Partner

(DACH region)

Quindoo - it Solutions GmbH

Hochwachtstraße 24

AT-6330 Kufstein

Tel. +43 5372 208 11 0

christian.nemeth(at)quindoo(dot)at

www.quindoo.at

System Partner

(Germany)

I&L Biosystems GmbH

Königswinterer Str. 409

53639 Königswinter

Tel. +49 2223 9192 0

info(at)il-biosystems(dot)de

www.il-biosystems.com

Marketing and Product Partner

(worldwide)

Genedata GmbH

Landsberger Str. 84

80339 Munich

Tel: +49 89 4581 9010

Fax: +49 89 4581 9015

europe(at)genedata(dot)com

www.genedata.com

Downloads

-

SDC Brochure

Download SDC information brochure in PDF format

-

SDC Touchpanel PC Flyer

Download SDC Touchpanel PC flyer in pdf format.

-

SDC Gateway End User License Agreement

Download the SDC Gateway EULA.

-

SDC Software License

Download the SDC software license.

-

SDC Software Service Contract

Download the SDC software service contract.

-

SDC Lite: Lightweight Data Conversion Tool

Sm@rtLine Data Cockpit Lite (SDC Lite) can import the system export files from Roche Cedex® Bio and Cedex® Bio HT analyzers. The results can be transformed between the system unit and a lab unit. The data can be exported into an excel file with a tab for CAL, QC, Results and Report. The Report page is user defined and can also be saved as a PDF Document.

Contact us for more Information.

News

JSat Automation and AGU Join Forces to Drive Innovation in Laboratory Automation

January 23, 2025 – JSat Automation, a leader in cutting-edge laboratory automation solutions, and AGU, a global provider of state-of-the-art scientific data management and

Genedata and AGU announce their partnership

Genedata and AGU announce partnership to further automate and simplify data capture from instruments based on ISO 27001 and ISO 9001 standards.

Körber and AGU announce their partnership

Körber and AGU announce their partnership to further improve the digital transformation of laboratory workflows and MES in the pharmaceutical industry. Körber, the global leader

SDC webinar for SDC major version 3

We, the AGU Industrial IT Team would like to thank the participants of our first SDC Webinar. Our team remains committed to providing high-quality services

SDC Webinar for SDC Major Version 3

We are pleased to announce the new version V3 of our Sm@rtLine Data Cockpit (SDC). SDC has now been available to our life science customers

Tetrascience publishes press release for AGU partnership

TetraScience, the Scientific Data Cloud company, and AGU, a leading provider of middleware that connects to a wide range of sensors and analyzers, today announced